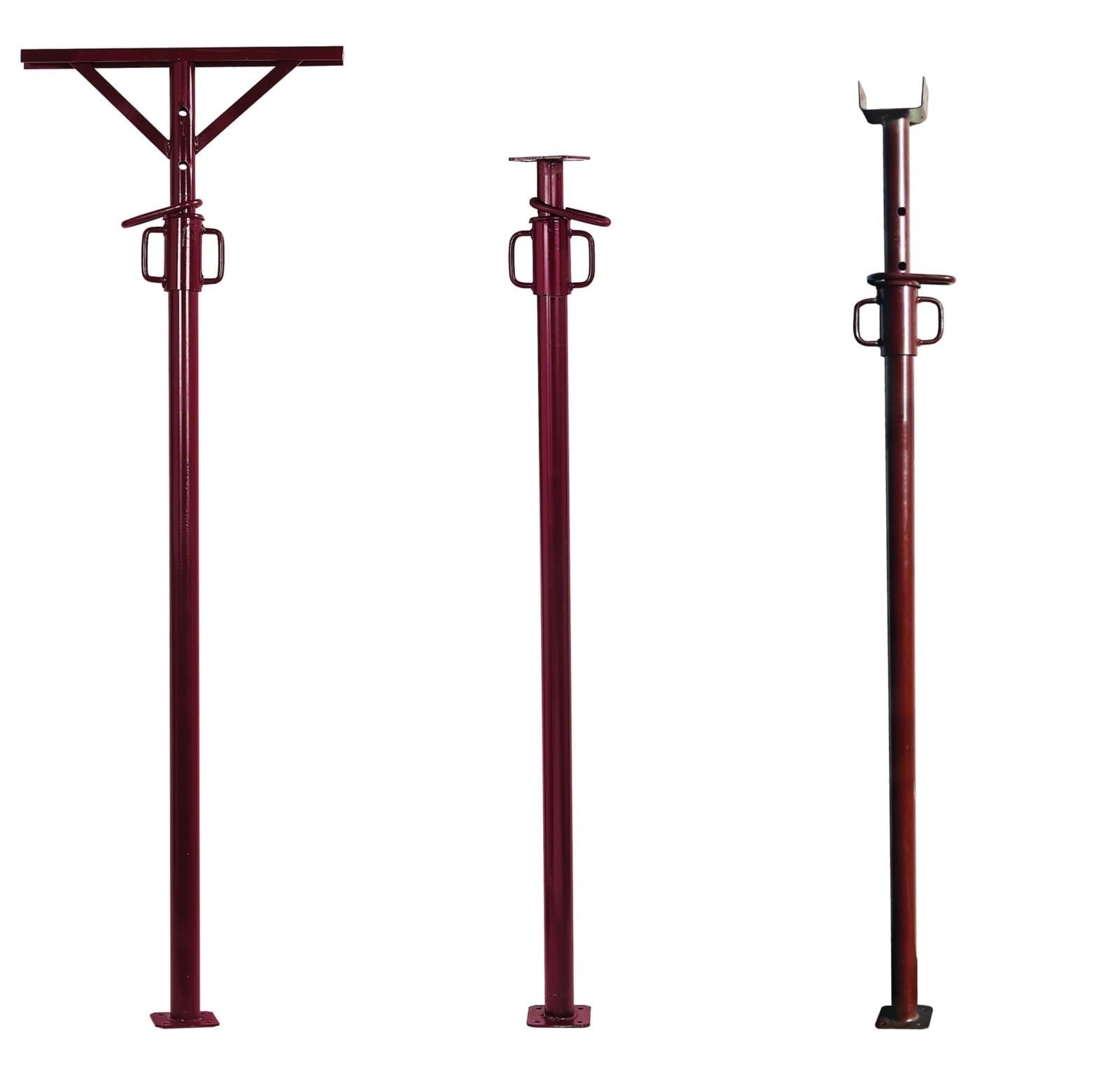

STANDARD TELESCOPIC PROP – Italian Model

Villalta offers a wide range of shoring systems, in different versions and e models.

This is a strong and telescopic prop with fixed cross, for its utilization, it is necessary to discharge the load in the centre, to not compromise its stability.

It is supplied with a dip painting finishing, which has a with minimum durability as per standard test ASTM D2247-87 in humidity chamber, brown colour RAL 8015

Supplied in pallets of 100 pcs each.

Technical features:

- Steel tube S235JRH

- Sleeve L 135 mm, mm pitch thread, with welded handles

- Safety pin Ø 14 mm, to fix the outer and inner tubes

- Sliding washer and sleeve protection

- Flat bottom plate 120x120x4.5 cm, to distribute the load to the floor

- Manufactured according to UNI EN 729-2: 1996

The double plates standard telescopic props is the most popular and used prop in Italy and abroad, thanks to its affordability, light and resistance.

It can solve every load capacity need up its maximum extension of 5,5 mt height and it can be combined with the most accessories of walk slab system.

Standard finishing: dip painting with minimum durability as per standard test ASTM D2247-87 in humidity chamber, brown colour RAL 8015, or, upon request, it can be hot dip galvanized, according to UNI EN ISO 1461 UNI EN 40 norm.

Technical features:

- Steel tubes S235JRH

- Male thread welded on the outer tube; it is made through rolling process, which grant a fine adjustment of the prop, and ensure stability and a greater loading capacity.

- Internal tube with punched holes every 100 mm for height adjustment

- Sleeve L 135 mm, with 8 mm pitch thread and welded handles

- Safety pin Ø 14 mm, to fix the outer and inner tubes

- Sliding washer and sleeve protection

- Flat plates 120x120x4.5 cm, to distribute the load to the floor

- Anti-shearing system for maximum safety

- Manufactured according to UNI EN 729-2: 1996

Upon request, we can supply:

- Quick release device, for a rapid prop removal

- Reinforced base, which is made welding a tube with a higher thickness close to the bottom plate

- Customizations: sticking personalized labels

The “U” head prop is manufactured with a welded fork on the top, so it is possible to lay directly a wooden beam on its head without any other accessories

It is supplied with a dip painting finishing, which has a with minimum durability as per standard test ASTM D2247-87 in humidity chamber, brown colour RAL 8015

Technical features:

- Steel tubes S235JRH

- Sleeve L 135 mm, with 8 mm pitch thread and welded handles

- Safety pin Ø 14 mm, to fix the outer and inner tubes

- Sliding washer and sleeve protection

- Bottom flat plate 120x120x4.5 cm, to distribute the load to the floor

- Fork 100x110x55 mm

Manufactured according to UNI EN 729-2: 1996

| Materials | |

|---|---|

| Leaflet | Download file |

| Maintenance Manual | Download file |

| Certifications | Contact VILLALTA SRL directly |

| Price offer | Request one |